English

Products

Die Blanks

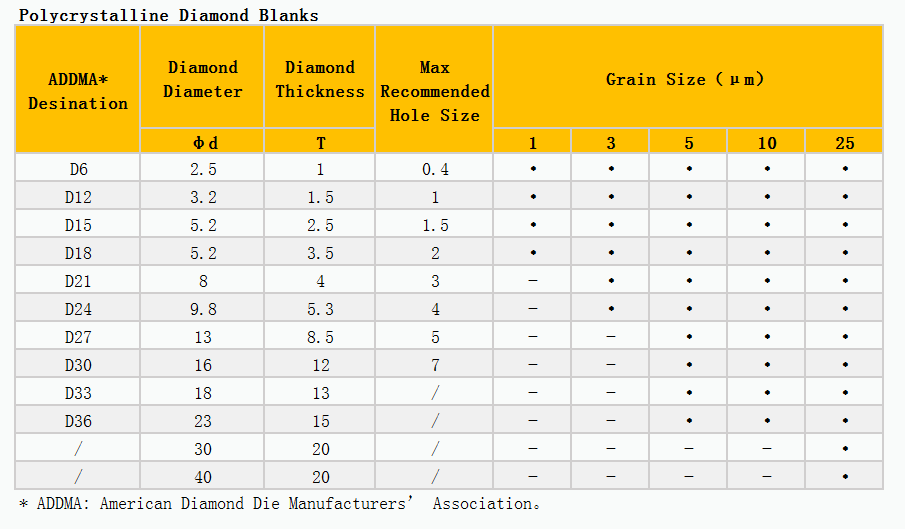

SLT Provide Synthetic Single Crystal Diamond Blanks and Polycrystalline Diamond Blanks.

Product Description

Die Blanks

1. Product Introduction of Die Blanks

SLT Provide Synthetic Single Crystal Diamond Blanks and Polycrystalline Diamond Blanks.

·SSCD(Synthetic single crystal diamond) is a synthetic diamond under controlled conditions. It has high purity, no impurities and no cracks. These quality characteristics also make the life of the wire drawing die stable and predictable.

·These specifications of PCD drawing die blanks are suitable for various types of drawing applications and are especially suitable for drawing dies with high consumption due to their economical cost.

2.Product Parameter (Specification) of Die Blanks

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk čeština

čeština Ελληνικά

Ελληνικά Українська

Українська नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine slovenský

slovenský Lietuvos

Lietuvos