English

Steel PCD Copper Wire Drawing Die

PCD Wire Drawing Dies (polycrystalline wire drawing dies) with Cobalt base is a good product with close performance to imported polycrystal, with long lifetime, high finish, high mold concentricity, mold parameter control and other advantages.

Product Description

PCD Copper Wire Drawing Die

PCD Wire Drawing Dies (polycrystalline wire drawing dies) with Cobalt base is a good product with close performance to imported polycrystal, with long lifetime, high finish, high mold concentricity, mold parameter control and other advantages.

Feature:

1) Cobalt-based PCD wire drawing die blank contains metal bond, has good processing properties

2)Can use electric sparks, lasers, ultrasonic and other processes for processing

3)The presence of metal cobalt makes diamond easy to graphite at high temperatures

4)PCD die blank is suitable for processing and use at less than 650 degrees Celsius conditions

Advantages:

1)better surface finish

2)minimum friction

3)higher wear resistance

4)high effeciency

5)a wide range of grain and nib sizes

6)perfect characteristics of crack proof

7)smoothness, durability predicted

8)Good polishing of wire or tube surface

9)Fast delivery time at about 7-10 days after receive your payments

PCD Wire Drawing Dies-Co Base Application:

Recommended for requirements of middle and high quality of wires, such as: cutting wire, structural wire, metal wire, copper wire, aluminum wire, welding wire, stainless steel wire, spring wire, copper-plated wire and other various non-ferrous or non-ferrous metal wire.

Parameter

| TYPE | DIE SIZE (mm) | STANDARD TOLERANCE (um) | STANDARD CASES | |

| A | B | |||

| ND DIES | <0.04 | 0.5 | 25 | 5 |

| 0.04-0.07 | 0.5 | 25 | 5 | |

| 0.08-0.19 | 1 | 25 | 8 | |

| 0.2-0.39 | 1 | 25 | 8 | |

| 0.4-0.59 | 1 | 25 | 10 | |

| 0.60-0.10 | 2 | 25 | 10 | |

| >1.0 | 3 | 30 | 15 | |

| PCD DIES | D6 | 0.10-0.15 | 25 | 7 |

| D12 | 0.10-0.80 | 30 | 15 | |

| D15 | 0.50-1.50 | 30 | 15 | |

| D18 | 1.00-2.30 | 30 | 15 | |

| D21 | 1.60-3.40 | 30 | 15 | |

| D24 | 2.60-4.60 | 42 | 20 | |

| D27 | 3.00-5.80 | 55 | 24 | |

| D30 | 4.00-11.20 | 55 | 24 | |

| D33 | 6.00-12.50 | 60 | 28 | |

| D36 | 8.00-13.50 | 70 | 35 | |

| D | 12.00-22.00 | 70 | 35 | |

| D | 20.00-32.00 | 85 | 40 | |

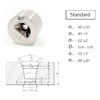

Shapes/drawing Reference

| Wire | Hard Wire | Soft Wire | |||

| Regular Standrad | Stainless steel | Copper-clad steel | Tungsten, tantalum | Copper wire | Aluminum wire |

| Antry Angle | 80° | 80° | 80° | 80° | 80° |

| Lubrication Angle | 35° | 35° | 35° | 35° | 35° |

| Reduction Angle | 14°±2° | 14°±2° | 12°±2° | 16°±2° | 18°±2° |

| Bearing Length | 0.2-0.5D | 0.2-0.6D | 0.2-0.8D | 0.2-0.5D | 0.2-0.5D |

| Relief Angle | 25°±2° | 25°±2° | 25°±2° | 25°±2° | 25°±2° |

| Exit Angle | 60° | 60° | 60° | 60° | 60° |

PCD dies- Co base have two different die blank: Self-Supported Die Blanks

& Tungsten Carbide Supported Die Blanks.

Dies with tungsten carbide supported eie blanks can withstand greater pull, more used in the manufacture of large aperture mold embryo, pulling a thicker diameter of wire - 3mm or more wire is recommended with carbide ring.

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk čeština

čeština Ελληνικά

Ελληνικά Українська

Українська नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine slovenský

slovenský Lietuvos

Lietuvos