English

PCD Diamond Wire Drawing Semi-Finished Dies

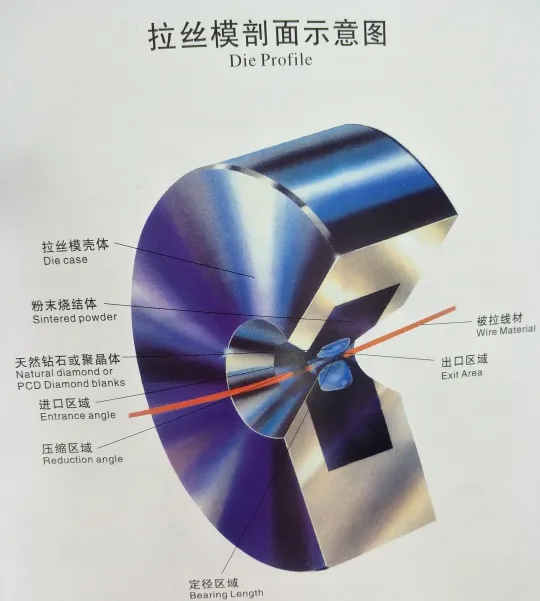

PCD Wire Drawing Dies (polycrystalline wire drawing dies) is composed of diamond powder under the action of Metal Catalyst (silicon), which is sintered by high pressure and high-temperature process.It can ensure the roundness of the wire and has a high surface finish, drawing life is long, it is difficult to appear mold wear and flat line phenomenon in even in a long time drawing process.

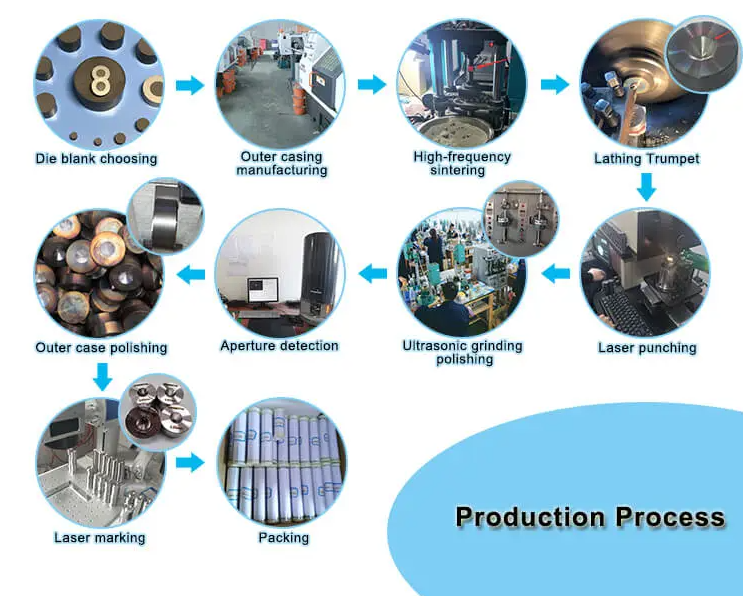

Product Description

Diamond Wire Drawing Semi-Finished Dies

Semi-PCD Wire Drawing Dies (polycrystalline wire drawing dies) is composed of diamond powder under the action of Metal Catalyst (silicon), which is sintered by high pressure and high-temperature process.It can ensure the roundness of the wire and has a high surface finish, drawing life is long, it is difficult to appear mold wear and flat line phenomenon in even in a long time drawing process.

Feature:

1.Under strict process control conditions, diamond microcrystalline particles form a diamond fitness combination, so that it has similar high hardness and high thermal conductivity as natural diamond

2.Because of the irregular arrangement of diamond micro-powder, so that polycrystalline diamond performance is anisotropic, processing need not consider its orientation, and has better toughness and wear resistance.

Advantages:

1.good durability

2.high efficiency

3.a wide range of grain and nib sizes

4.perfect characteristics of crack-proof

5.smoothness, durability predicted

6.Good polishing of wire or tube surface

7.Fast delivery time at about 7-10 days after receiving your payments

PCD Wire Drawing Dies-Si base application:

It is widely used to drawing all kinds of wire such as electronic devices, radar, television, instrumentation, and aerospace, such as the use of high-precision wire, as well as commonly used tungsten wire, molybdenum wire, stainless steel wire, wire cable wire and a variety of alloy wire.

Parameter Table

| TYPE | DIE SIZE (mm) | STANDARD TOLERANCE (um) | STANDARD CASES | |

| A | B | |||

| ND DIES | <0.04 | 0.5 | 25 | 5 |

| 0.04-0.07 | 0.5 | 25 | 5 | |

| 0.08-0.19 | 1 | 25 | 8 | |

| 0.2-0.39 | 1 | 25 | 8 | |

| 0.4-0.59 | 1 | 25 | 10 | |

| 0.60-0.10 | 2 | 25 | 10 | |

| >1.0 | 3 | 30 | 15 | |

| PCD DIES | D6 | 0.10-0.15 | 25 | 7 |

| D12 | 0.10-0.80 | 30 | 15 | |

| D15 | 0.50-1.50 | 30 | 15 | |

| D18 | 1.00-2.30 | 30 | 15 | |

| D21 | 1.60-3.40 | 30 | 15 | |

| D24 | 2.60-4.60 | 42 | 20 | |

| D27 | 3.00-5.80 | 55 | 24 | |

| D30 | 4.00-11.20 | 55 | 24 | |

| D33 | 6.00-12.50 | 60 | 28 | |

| D36 | 8.00-13.50 | 70 | 35 | |

| D | 12.00-22.00 | 70 | 35 | |

| D | 20.00-32.00 | 85 | 40 | |

Shapes/drawing Reference

|

Wire |

Hard Wire |

Soft Wire |

|||

|

Regular Standrad |

Stainless steel |

Copper-clad steel |

Tungsten, tantalum |

Copper wire |

Aluminum wire |

|

Antry Angle |

80° |

80° |

80° |

80° |

80° |

|

Lubrication Angle |

35° |

35° |

35° |

35° |

35° |

|

Reduction Angle |

14°±2° |

14°±2° |

12°±2° |

16°±2° |

18°±2° |

|

Bearing Length |

0.2-0.5D |

0.2-0.6D |

0.2-0.8D |

0.2-0.5D |

0.2-0.5D |

|

Relief Angle |

25°±2° |

25°±2° |

25°±2° |

25°±2° |

25°±2° |

|

Exit Angle |

60° |

60° |

60° |

60° |

60° |

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk čeština

čeština Ελληνικά

Ελληνικά Українська

Українська नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine slovenský

slovenský Lietuvos

Lietuvos