English

-

Bunching stranding wire solid stranding dies

Read More Send InquiryWire drawing is done by passing the metal wire through the hole of the Wire Drawing Die, and applying a pulling force to the wire at the exit side of the die. The wire is contracted and squeezed in the die cavity and gradually becomes thinner, and its speed increases near the exit of the die hole. Since the volume of the wire is constant, the decrease in cross section makes it stretched. In the center, there is a hole of a certain shape, such as round, square, octagonal or other special shapes. When the metal is pulled through the die hole, the size becomes smaller and even the shape changes.

-

Semi-Finished Polycrystalline Wire Drawing Die

Read More Send InquiryDiamond Wire Drawing Die made of Polycrystalline Diamond Blanks

Fine semi-finished products of Polycrystalline Diamond Drawing Die and laser drilling Semi-Finished products of Diamond Drawing Dies.

IW offers our customers semi-finished products of ND Die,PCD Die,Mono Die,and others,who are experienced die makers.

In order to save the die making cost and labor cost,they can purchase our semi-finished products.As well,it is easy to controll their own quality. -

Shaped Carbide Wire Drawing TC Dies

Read More Send InquiryWire drawing is done by passing the metal wire through the hole of the Wire Drawing Dies, and applying a pulling force to the wire at the exit side of the die. The wire is contracted and squeezed in the die cavity and gradually becomes thinner, and its speed increases near the exit of the die hole. Since the volume of the wire is constant, the decrease in cross section makes it stretched. In the center, there is a hole of a certain shape, such as round, square, octagonal or other special shapes. When the metal is pulled through the die hole, the size becomes smaller and even the shape changes.

The best material depends on the wire you draw and the quantity you draw. Contact us to help you choose the most economical solution and reduce the total cost of ownership of your diamond drawing dies. -

Monocrystalline MCD SSCD Drawing Dies

Read More Send InquiryMonocrystalline Diamond is a synthetic diamond under controlled conditions, which has the characteristics of high purity, no impurities and no cracks.

These quality characteristics also make the service life of the drawing die more stable. -

Nano Coated Diamond Wire Drawing Dies

Read More Send InquiryThe nano-diamond coating drawing die is made of cemented carbide (WC-Co) as the substrate, and the surface of the inner hole is coated with a micro-nano-scale diamond composite coating by chemical vapour deposition (CVD), which is ground and polished.

-

TC Tungsten Carbide Diamond Wire Drawing Die

Read More Send InquiryTC Wire Drawing Dies (Tungsten Carbide Wire Drawing Dies) are widely used in applications that require high temperature, impact resistance and only short-term use. This is made possible by the low price of tungsten carbide dies. Because of its ease of processing and low cost, tungsten carbide is also selected as the die blank material for most special-shaped molds and stranding dies.

-

PCD Diamond Wire Drawing Semi-Finished Dies

Read More Send InquiryPCD Wire Drawing Dies (polycrystalline wire drawing dies) is composed of diamond powder under the action of Metal Catalyst (silicon), which is sintered by high pressure and high-temperature process.It can ensure the roundness of the wire and has a high surface finish, drawing life is long, it is difficult to appear mold wear and flat line phenomenon in even in a long time drawing process.

-

Steel PCD Copper Wire Drawing Die

Read More Send InquiryPCD Wire Drawing Dies (polycrystalline wire drawing dies) with Cobalt base is a good product with close performance to imported polycrystal, with long lifetime, high finish, high mold concentricity, mold parameter control and other advantages.

-

Diamond PCD ND Wire Drawing Dies

Read More Send InquiryND Wire Drawing Dies (Nature Diamond wire drawing dies), it’s die blank raw material diamond is la type diamond. These diamonds contain certain nitrogen impurities (0.1% order of magnitude), and these nitrogen impurities are combined into small aggregates. With very high hardness and good thermal conductivity and photothermal properties, in the industrial field is widely used in conductor industry. Its physical properties are: density 3.515g/cm3; hardness: 1.25-10.76GPa.

-

Polycrystalline Mold PCD Diamond Wire Drawing Dies

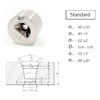

Read More Send InquiryPCD Die, also known as Polycrystalline Diamond Die, is widely used for wire drawing because of its strength and sustainability. We manufacture PCD dies of size range 0.100mm to 14.00mm. The type of PCD blank to be used depends on the material to be drawn and the process. These blanks come in two varieties, self-supported and Tungsten carbide supported. They come in grains size of 3, 5, 10, 25, and 50 microns. The profile of the die plays a crucial role in the wire drawing process. Given below are the specifications of the profile of the die depending on the material to be drawn.

-

Microscope

Read More Send InquiryIt has the advantages of high performance, high quality, and high cost performance.

-

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk čeština

čeština Ελληνικά

Ελληνικά Українська

Українська नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine slovenský

slovenský Lietuvos

Lietuvos